Secondary Containment

Dura Life Containment Systems, the leading provider of secondary containment on the market, are the most common sense alternative to high-maintenance earth dikes and costly concrete.

We are able to provide you with systems that are of the highest quality, with the durability to match. Each Dura Life Containment System is professionally engineered, using Finite Element Analysis (FEA). This process efficiently pinpoints and eliminates stress points, producing the most environmentally safe system in the industry. Systems are designed to exceed the Environmental Protection Agency (EPA) Standards and EUB (G55) regulations for oil spill prevention and countermeasures.

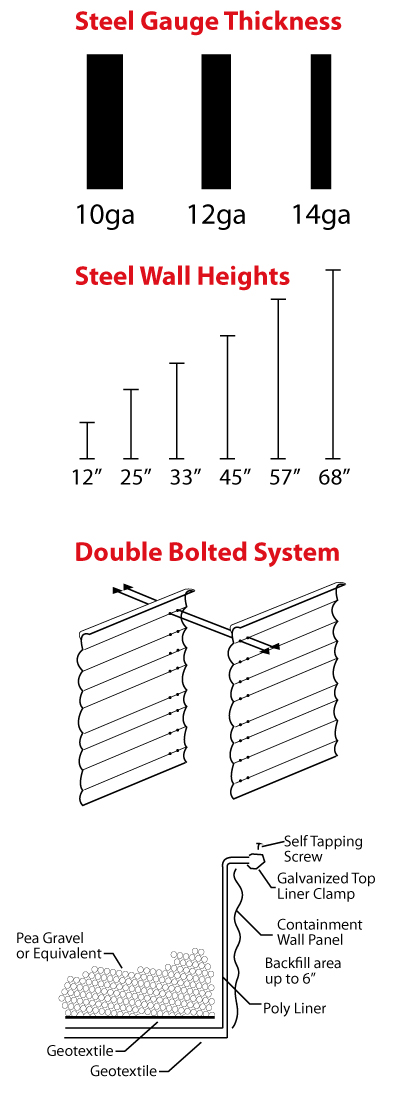

We use only the highest quality, chemically treated, galvanized steel. The 65,000 PSI, heavy-duty 10, 12 and 14 gauge corrugated steel construction resists rust and corrosion even in the harshest environments. Steel wall heights are available in 12”, 25”, 33”, 45”, 57” and 68” in order to best match each containment system. Our steel systems ensure longevity, by forming each sidewall sheet with flanged tops and double bolted seams, providing twice the strength while maintaining sidewall shape and failsafe seals.

To prevent further leakage when, and if, a spill occurs, our high-grade liners are expertly sealed at each seam. Dura Life Containment Systems come in four standard shapes. However, custom site creations are also available. Custom Containment Systems fit anywhere, allowing tight installations between structures possible. Our custom corner systems can be installed with as many as 14 different angles to work around obstacles such as pipes, buildings and control equipment.

Dura Life Containment Systems can be easily disassembled, moved and reassembled to a new site, making relocating easy. Additionally, expansions and modifications to an existing system is easily done by adding more panels and liners.